Traditional Programming

Effective for high-volume, repetitive tasks but falls short when tasks require flexibility or frequent changes.

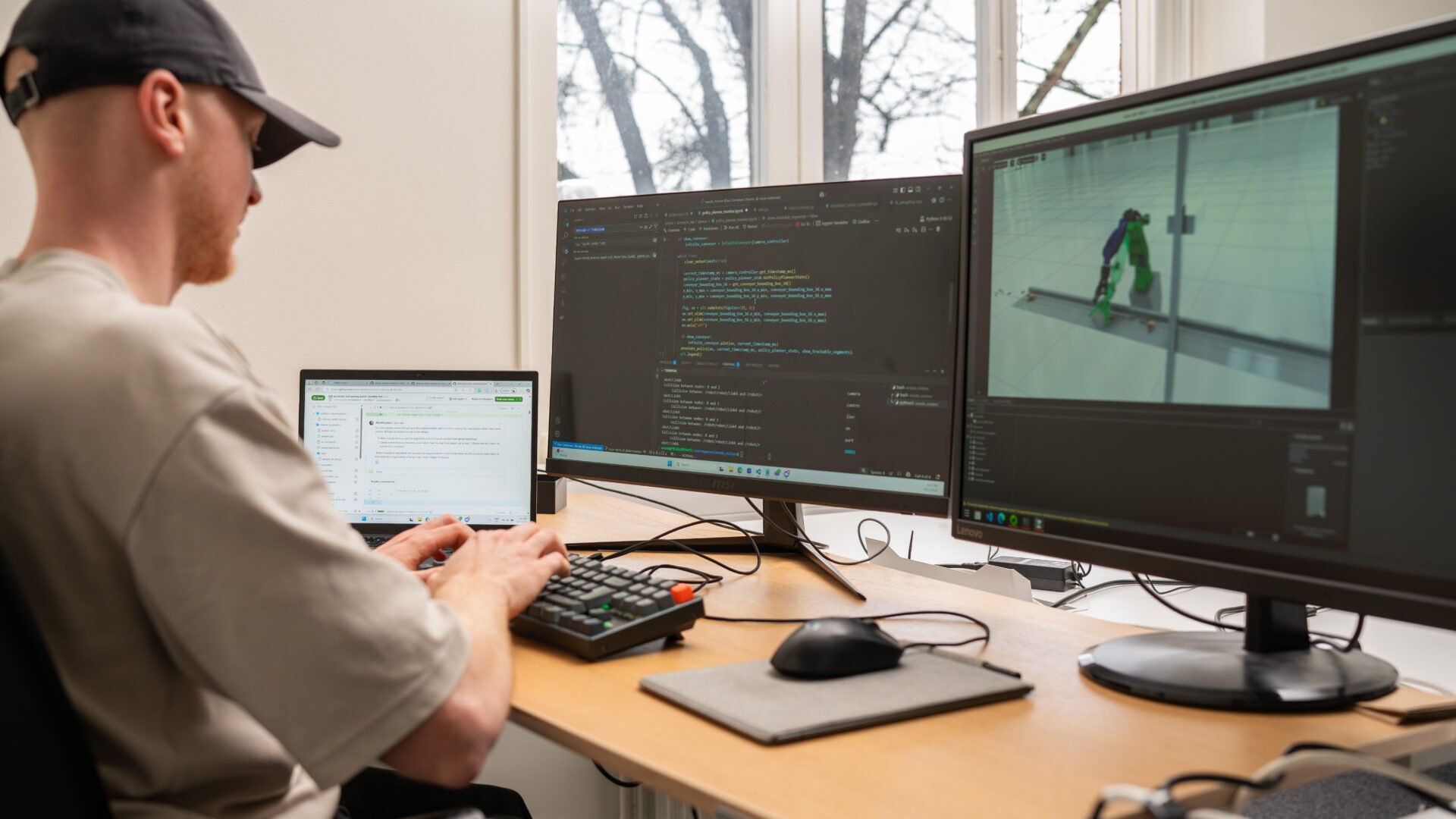

Most industrial robots are designed for repetitive, high-volume production. But what happens when your tasks require flexibility, frequent updates, or smaller batches? That’s where traditional programming breaks down—and AgilePath takes over.

Drawing on years of experience developing robot applications that push the boundaries of industrial robotics, AgilePath is the path planning solution we wished we had. It embodies our vision of what a path planning solution should be: flexible to integrate, capable of utilizing the full motion spectrum of the robot, and easy to use.

AgilePath maintains a collision model of the robot environment, ensuring collision-free trajectories.

AgilePath explores all available options to reach the desired tool poses. Get rid of production stops caused by joint limit and singularity violations.

AgilePath optimizes not just the next move but the entire process – enabling faster cycle-times with minimal reorientation motions.

AgilePath plans in terms of standard industrial robot commands. The output is robot programs in the vendor language, e.g. ABB Rapid or Yaskawa Inform.

AgilePath is designed from the ground up to be flexible and integrable in existing processes and workflows. Deployment options are flexible.

AgilePath consumes gemoetry- and pointcloud data for updating the collision model at runtime.

AgilePath brings value to tasks that traditional programming struggles to automate. Below are examples from real-world scenarios – and the benefits that make it possible.

“With AgilePath, we were able to completely eliminate manual programming from a very complex pick-and-assemble application with a bimanual robot.

It is basically impossible to foresee all possible situations that can occur in a sensor-driven application, so manual programming is virtually guaranteed to result in production stops at some point – it is just a matter of time.

Enodo AgilePath not only saved us months of work by removing the need for manual programming, but more importantly resulted in a much more robust application without production stops . This technology enables development and deployment of sensor-driven applications with confidence.”

- Ivan Lundberg, CEO of Cobotic

About Enodo Robotics

Let’s explore how Enodo’s solutions can solve your automation problems.