Picks randomly oriented parts from a bin

Autonomous Pick-and-assemble of electronics components

What are the possibilities when you combine industry-leading solutions for pose estimation and path planning? Endless! Together with our friends and partners at Cobotic and RSP, we set out to exemplify this with an application involving precise manipulation of electronics components.

The task consists in picking components from a bin and inserting them on a circuit board, a task requireding sub-millimeter precision to complete.

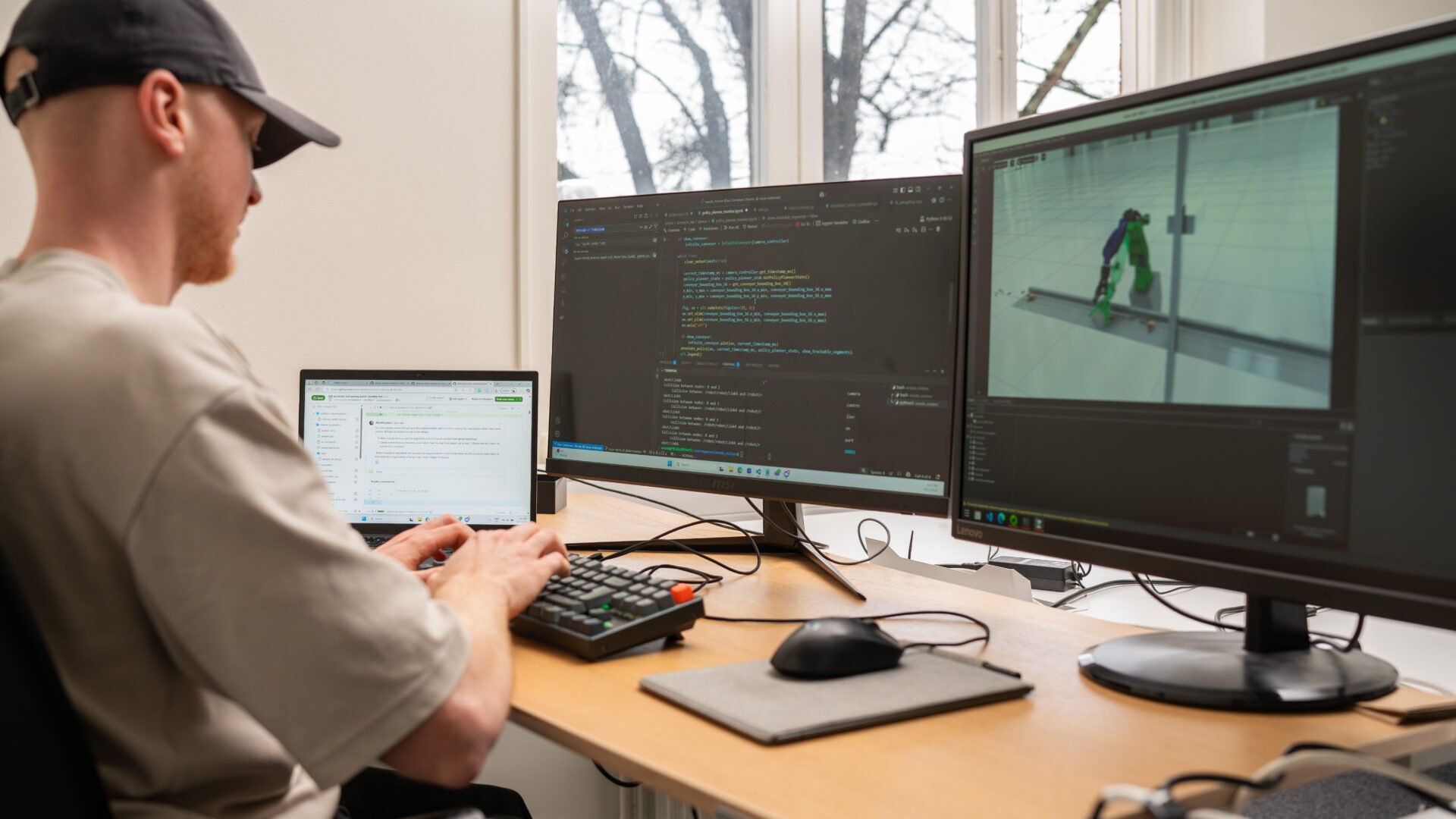

The bi-manual robot from ABB is equipped with cameras on its end-of-arm-tooling. Images from these cameras are used by PoseStream from Cobotic for real-time pose estimates of the components. The motion programming for tasks like this quickly become extremely complex and error-prone, because of the large tree of possibilities of component poses, handover positions, etc. With AgilePath, we solved this by insted generating robot programs on the fly – guaranteeing that only kinematically feasible and collision-free paths are executed.

How it works

Vision by Cobotic

PoseStream detects each part’s exact position and orientation inside the bin, even in cluttered scenes.

Motion by Enodo AgilePath

AgilePath generates optimal motions in real time. From pick, to handover, to precise assembly.

RAPID program upload and execution

AgilePath outputs programs in the vendor language (in this case, ABB RAPID), which are uploaded and executed at runtime.

Flexible by design

Thanks to its modular architecture, this and similar applications combining pose estimation and path planning can be deployed with any robot brand.

Powered by Collaboration

Ready to automate smarter?

Let’s talk about how AI vision and AgilePath can enable your next robot application.