Rebar assembly. Reinvented through robotics

Rebar assembly represents a critical bottleneck in many construction projects. This innovative automation solution, developed in partnership between Skanska, ABB, Husqvarna, and Enodo Robotics, demonstrates how advanced robotics can revolutionize traditional construction processes.

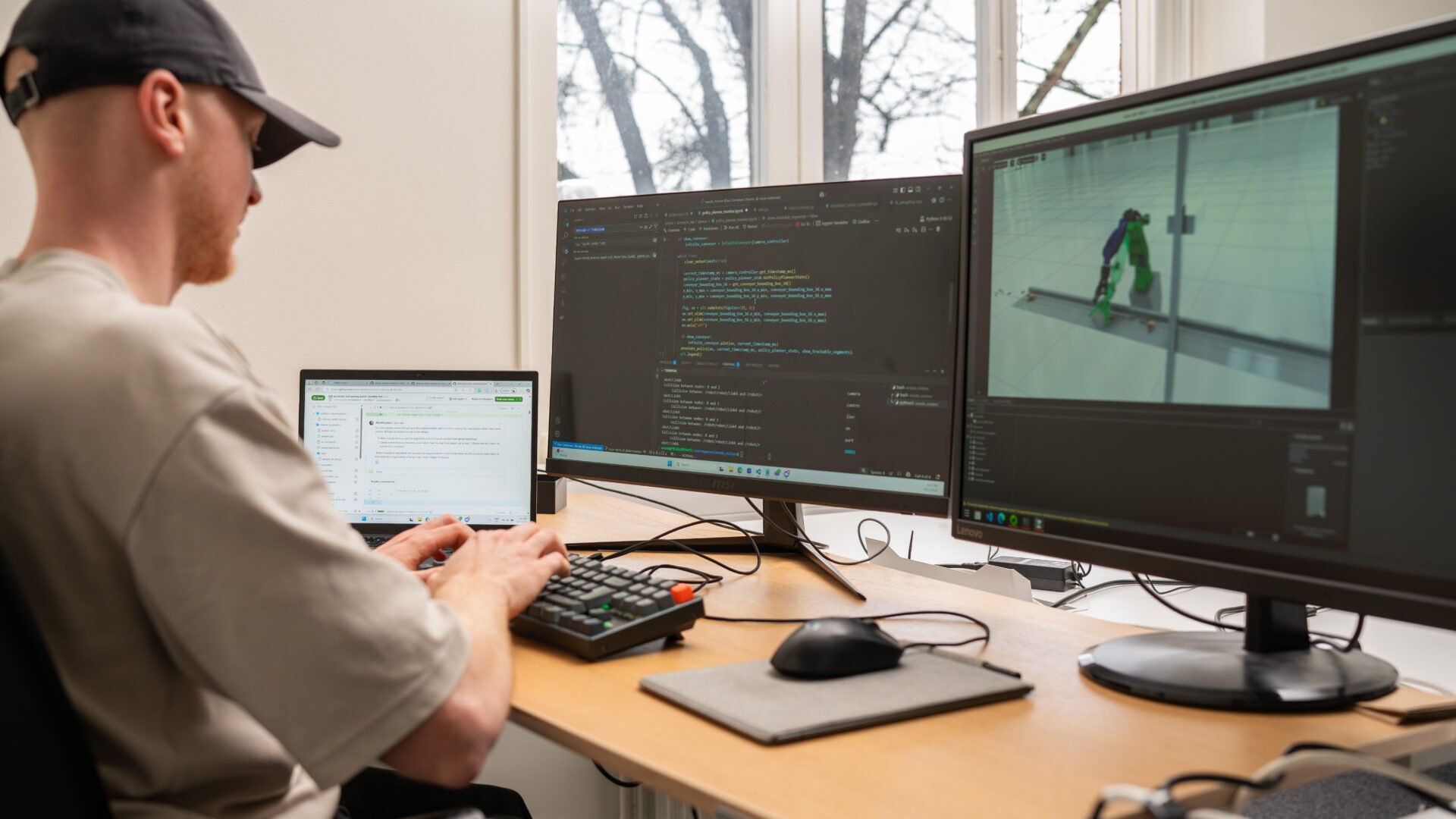

Enodo Robotics developed all software in this project, translating rebar cage designs directly into coordinated robot programs. The system integrates CAD/BIM design models with fully automated robot programming, eliminating manual motion programming entirely. This project is a great example of how path planning customized to a specific application area can unlock single-unit production with robots.

How it works

Input: BIM model

Engineers use Tekla, Revit or similar tools to create the rebar cage design. This digital asset is the input to the system.

Automatic planning

Software provided by Enodo analyse the BIM model and generates a robot program for assembling the structure.

Output: robot program

The robot executes the program in a live workcell, assembling the cage safely and accurately.

Learn more about this project

Thanks to its modular architecture, Bin2Board can be deployed on a wide range of robots – not just ABB. Smart, scalable, and ready for production.

Powered by Collaboration

Ready to automate smarter?

Let’s talk about how AgilePath or a custom solution can support your production needs.